Power plant construction - Anstatt Schienenfahrzeuge Kraftwerksanlagenbau GmbH

Main menu:

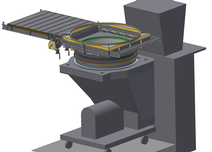

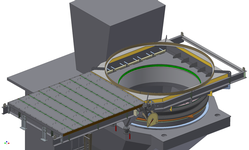

Wanderrostfertigung im Werk Grimma

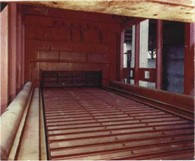

Auslieferung Schuppenwanderrost

für die Stadtwerke Kaiserslautern

für die Stadtwerke Kaiserslautern

Power plant construction: Testimonials (selection)

Lurgi Lentjes Service – Nikola Tesla Thermal Power Plant, Obrenovac (Serbia), Unit 3

• Rehabilitation of DGS 100 S fan mills

• Rehabilitation of afterburning grates (scale traveling grate)

• Revamping of fuel delivery system

B & B Energie Calau

• Delivery and erection of a biomass combustion plant with reciprocating grate; grate surface 12 m²

Stadtwerke Kaiserslautern (multi-utility)

• Delivery and installation of a traveling grate with rotatable grate bars for coal; grate surface 32 m²

• Delivery of duct sections and ash hoppers

Papierfabrik Mochenwangen (paper factory)

• Delivery and installation of a traveling grate with rotatable grate bars for coal; grate surface 28 m²

RWE – Neurath Power Plant

• Delivery of slide gate valves for flue gas recirculation duct before mill

Eins – Energie Chemnitz

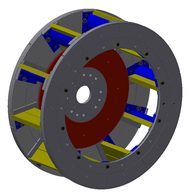

• Refurbishment of impact wheels including body for the NV 40 fan mill

Power plant construction: Travelling grate

Anstatt - Bar travelling grate: Grate surface up to 16 m² (historical drawing)

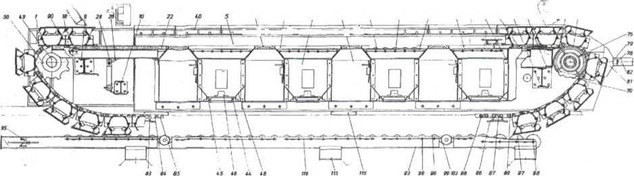

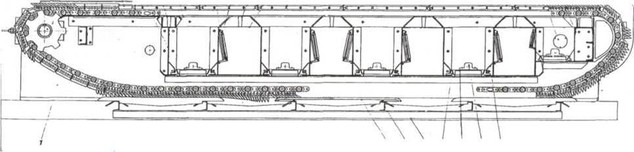

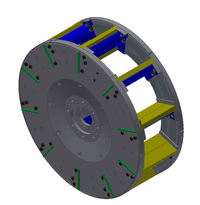

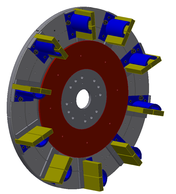

Anstatt - Travelling grate with rotatable grate bars: Grate surface up to 33 m² (historical drawing)

Chain with grate bar Grate surface and grate bars Driveshaft and bearings

Air zone Primary air and recirculation Swinging ash cut-off gate Driveshaft

gas duct

Bar travelling grate Travelling grate with rotatable Grate construction site installation

grate bars during grate refurbishment

Reciprocating grate: Fuel feed Combustion chamber and grate Flatbed ash removal

Chain grate for flame-tube boilers (Steam production from 3.2 TPH to 10 TPH)

NV40-Beater wheel: Front Rear Crass-section

Slide gate valve before mill (shown without flue gas recirculation duct)